Stepper drives for both AC and DC power applications are ideal for high-performance indexing applications offering microstepping capabilities up to 50000 steps per revolution with no need for feedback systems. Image used courtesy of the Association for Advancing Automation.

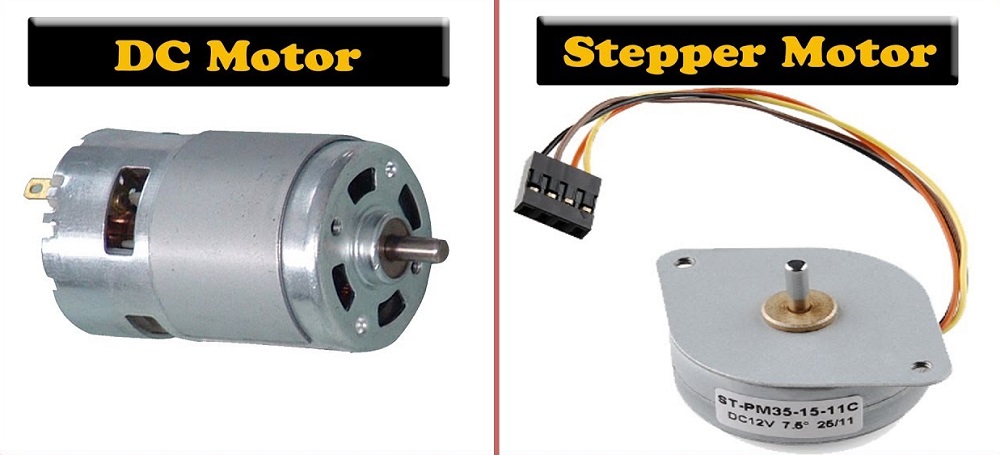

Dc Motor Vs Stepper Motor Vs Servo Motor Which To Choose

There are several types of stepper motors are available in todays market over a wide range of sizes step count constructions wiring gearing and other electrical characteristics.

. The Brush DC Motors have two terminals. FOC offers an advantage over other types of motor control because it has a significant increase in efficiency as motor speeds reach their limit. In wave mode only one phase at a time is energized see Figure.

There are four main types of DC motor all of which are used for different applications. DC Motor speed can be controlled by varying the supply voltage and is available in a wide range of voltages although the most common form is 12 24V with some of the advantages being. The servo motor consists of a DC motor but not Servo motor.

Speed control over a wide range. DC motors are about 30 more efficient than AC motors. A permanent magnet DC PMDC motor is a type of DC motor whose field poles are made up of permanent magnets.

Like all motors the stepper motors also have a stator and a rotor but unlike a normal DC motor the stator consists of individual sets of coils. Thus the gear design rotation speed of the servo is much slower but. DC Current is used to energize the stepper motor magnetic coil.

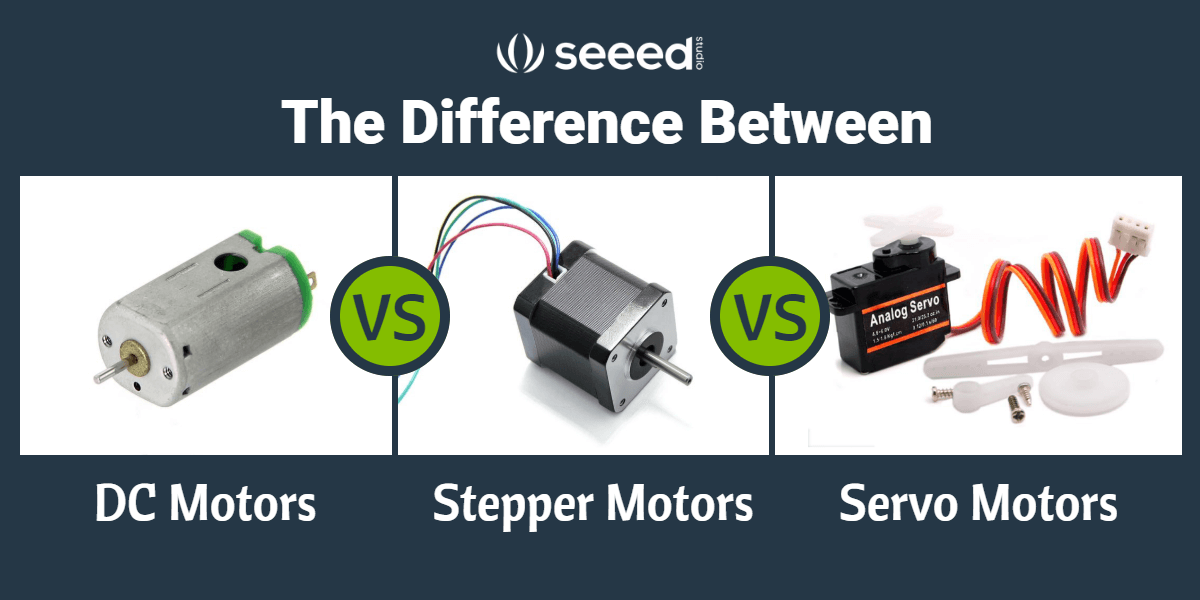

DC motors spin at high rpm and very low torque. While this makes driving stepper motors more complex there is a major advantage over brushless DC motors. A stepper motor also known as step motor or stepping motor is a brushless DC electric motor that divides a full rotation into a number of equal steps.

It consumes less power. It also has the added benefit of. The classification of motors can be done based on the type of supply like AC motors DC motors.

Under these AC DC motors there are different kinds of motors comes as induction motor reluctance motor DC shunt PMDC stepper synchronous etc. These motors provide an excellent cost-effective alternative to pneumatic hydraulic and servo motor systems. They are also called DC compound motors.

The cross-sectional view of a 2-pole permanent magnet DC Motor is shown in Figure-1. Stepper Motor Interfacing with 8051 Microcontroller. It consumes more power than a stepper.

Their angular position can be specified with a great degree of accuracy. Torque can be increased by increasing current. There are four different driving techniques for a stepper motor.

The stator which includes the housing permanent magnets and brushes and the rotor which consists of the output shaft windings and. As we mentioned before compound DC motors are basically made up of a combination of series and shunt motors. In a PMDC motor the permanent magnet poles are radially magnetised and mounted on the inner periphery of the stator of the motor.

Construction of a Stepper Motor. A Brush DC Motor consists of two pieces. For lower speeds and smaller force requirements stepper motors provide good motion resolution.

Stepper motor interfacing with 8051 is very simple by using three modes like wave drive full step drive half step drive by giving the 0 1 to the motors four wires based on which drive mode we have to choose for running this motor. If you want to know everything about a DC motor DC motor types and their utilizations. Current in Stepper Motor.

Motors offer excellent controllability and are therefore used as the drive sources of various automated equipment. The stator also. We know that the main function of a motor is to change the energy from one form to another like electrical to mechanical.

When the voltage is applied across the two terminals a proportional speed is outputted to the shaft of the Brush DC Motor. Since they can be driven by an AC power supply and offer superb starting and stopping characteristics they are sometimes called AC stepper motors. A brushless DC BLDC motor showing the field windings that produce the magnetic field for rotation.

Torque can be increased by increasing current. The P5000 is a compact micro-stepping stepper drive optimized for high system performance with Kollmorgens industry leading POWERMAX II. Stepper Motor Driving Techniques.

For many applications the answer can be stepper motor systems consisting of a stepper motor a drive and a controller. Current in Servo motor. The number of coils will differ based on type of stepper motor but for now just understand that in a stepper motor the rotor consists of metal poles and each pole will be attracted by a set of coil in the stator.

This type of motor has both series and shunt field coils that are connected to the winding of an armature. For example if you want a motor to rotate exactly 270 degrees this would be near impossible to do with a general DC brushless motor without some form of feedback but would be a breeze. These field coils which are linked to the armature windings afford the essential amount of.

As these motors are capable to operate in discrete nature these are well suitable to interface with digital control devices like computers. The motors position can be commanded to move and hold at one of these steps without any position sensor for feedback an open-loop controller as long as the motor is correctly sized to the application in respect to torque and. A brushless DC electric motor BLDC motor or BL motor also known as an electronically commutated motor ECM or EC motor or synchronous DC motor is a synchronous motor using a direct current DC electric power supply.

Therefore a six wire stepper motor can be classified as a unipolar motor and a four wire stepper motor can be classified as a bipolar motor. DC motors use direct current to power the carbon brushes and commutator or electrically commutate the windings with a driver. Quick Starting Stopping Reversing and Acceleration.

In many cases a stepper motor is combined with various mechanical components such as a ball screw belt and pulley and rack and pinion to convert the motor rotation to a different type of motion needed to drive the equipment such as a linear actuator. However inside a servo motor there is an arrangement of gears that will take the high speed of the internal DC motor and slow it down while at the same time increasing the torque. The remaining two wires must be coupled to a voltage.

The motor itself is not unipolar or bipolar per se but manufacturers can classify stepper motors as unipolar or bipolar according to the number of lead wires. Three Phase AC Current is used to energize the servo motor magnetic coil. The KM Series of high-torque NEMA 23 34 and 42 60 90 and 110 mm stepper motors offers a wide range of models to suit most stepper applications.

Stepper systems provide some of the best features of the previously described motors in an economical way. Bipolar Stepper Motor Driving Circuit. However remember that the.

This article describes how users. With technology progress the advantages of unipolar are becoming less relevant and bipolar steppers are currently the most popular. It uses an electronic controller to switch DC currents to the motor windings producing magnetic fields which effectively rotate in space and which the.

As you may know a DC motor or a direct connection motor is referred to as any type of rotary electric motors that converts direct electrical energy into mechanical energy.

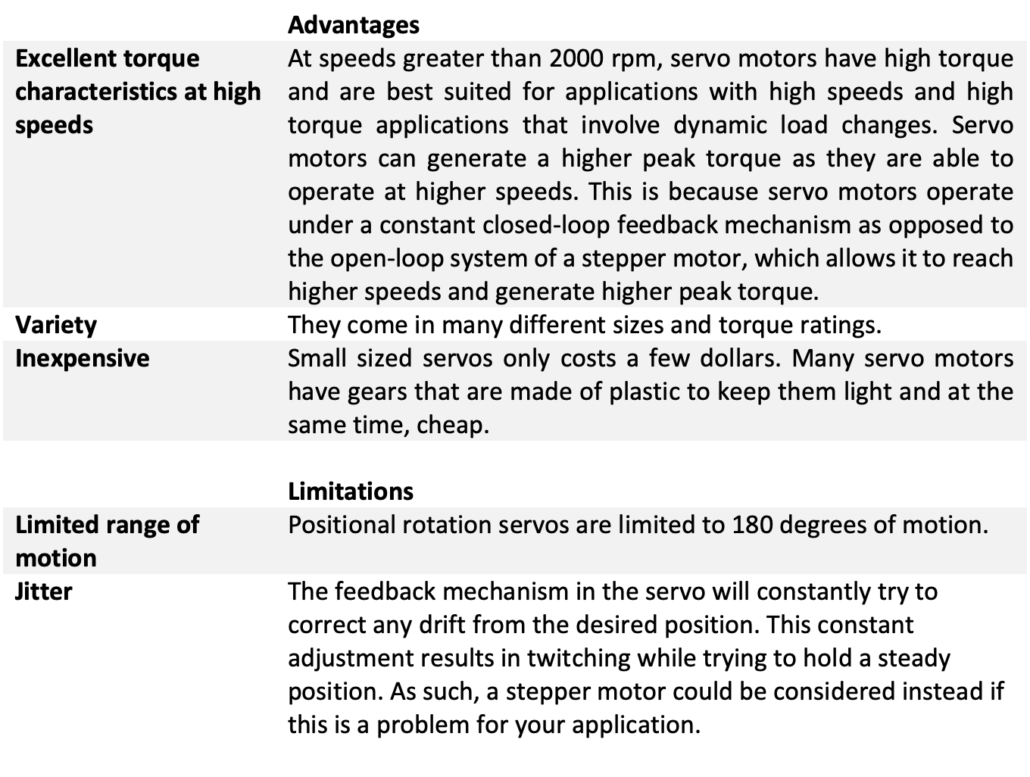

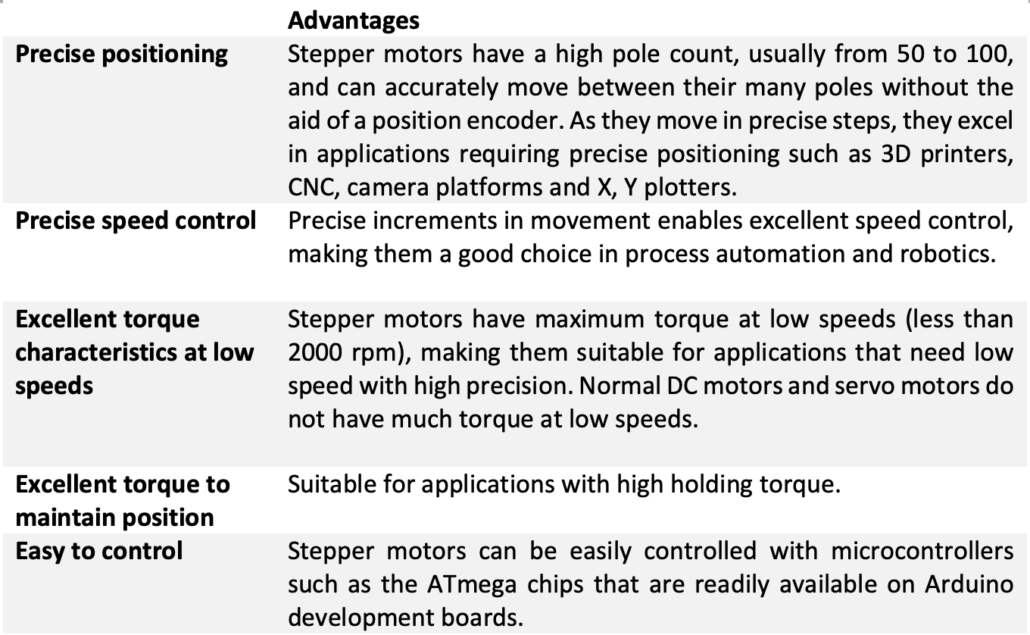

Advantage Disadvantages Of Servo And Stepper Motors The Engineering Knowledge

Dc Motor Vs Stepper Motor Vs Servo Motor Which To Choose

0 Comments